With an Altendorf sliding table saw, processing aluminium is child’s play.

Thousands of Altendorf sliding table saws have been working in the aluminium processing industry for years.

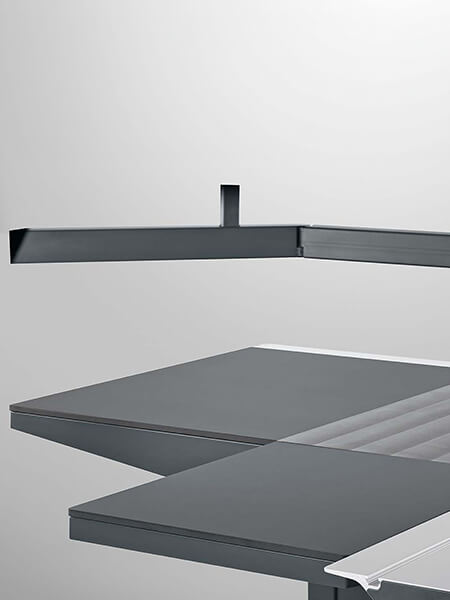

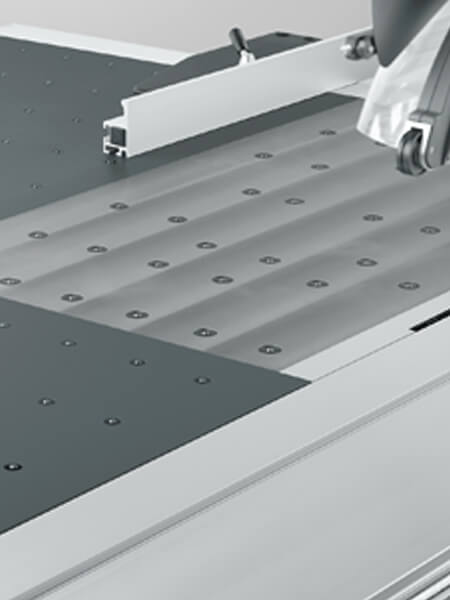

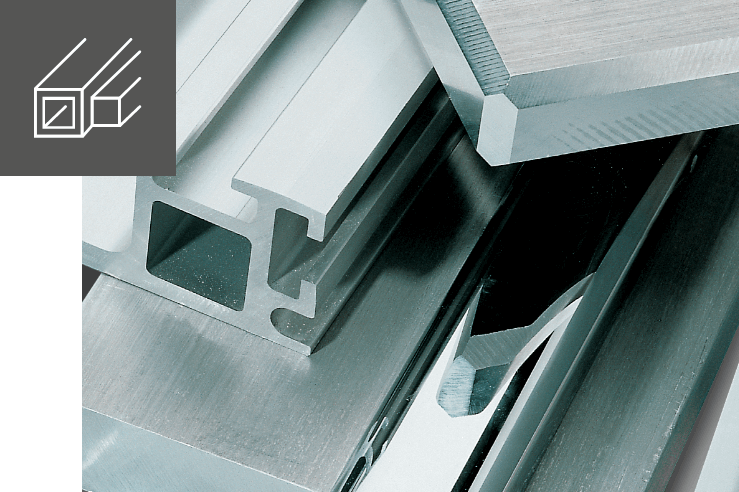

Our sliding table saws for aluminium are characterised by numerous equipment variants that have been specially developed for the complex challenges of aluminium processing. This is Altendorf precision that inspires.

Discover the wide range of applications for aluminium.

Aluminium is used in a variety of ways in different industries. Here we present some of the most common industries in which aluminium plays a significant role:

FAQs sliding table saws and aluminium

Which sliding table saw is the best?

Every Altendorf is a good decision.

Thanks to countless configuration options, we always have the right one for you. We will be happy to help you find the best machine for your budget, your requirements and to meet your orders. Our expert advisors from the service department are on hand to give you the right advice.

How safe are sliding table saws for aluminium?

There is no compromise when it comes to safety.

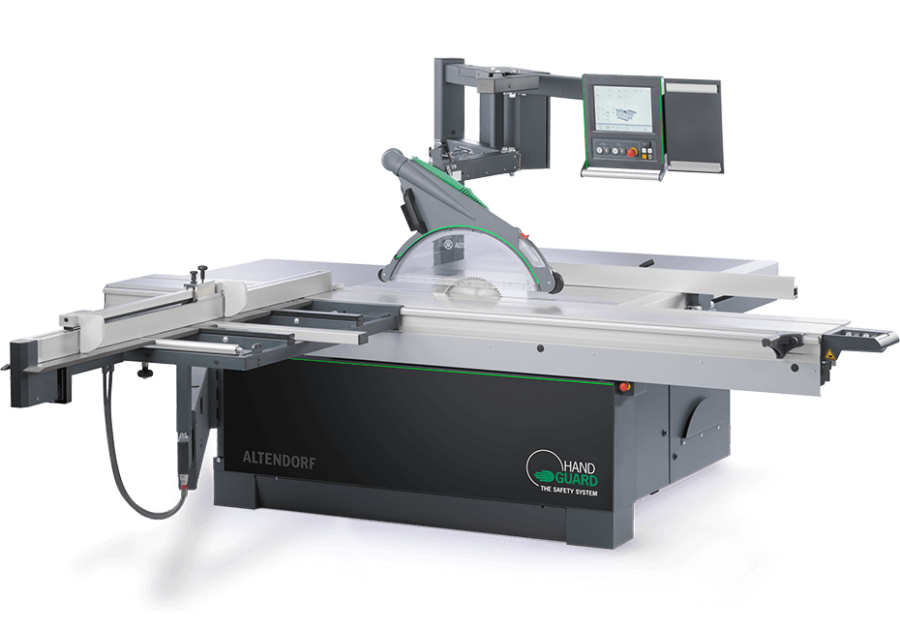

Cutting and sawing aluminium must not only be precise and clean, but also safe – especially with regard to the softness of the material. Our sliding table saws are equipped with HAND GUARD, a unique safety system. Should a dangerous situation arise, the system reacts in a flash and warns you with a visual signal. The saw unit is lowered and the saw blade stopped – the machine is then immediately ready for use again.

How long is the factory warranty?

An Altendorf sliding table saw for aluminium is an investment for the future

The factory warranty is for one year. If desired, you can purchase a warranty extension and extend it to 5 years.

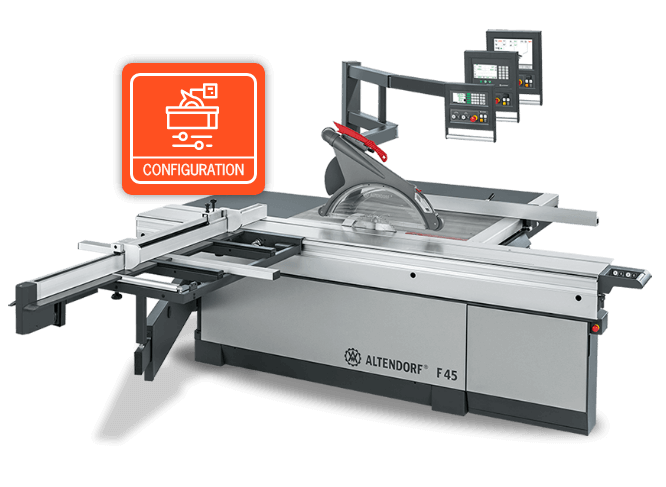

Equipment options for your new F 45 sliding table saw

Thanks to the modular machine concept, you can configure your F 45 individually – just as your application situation requires.

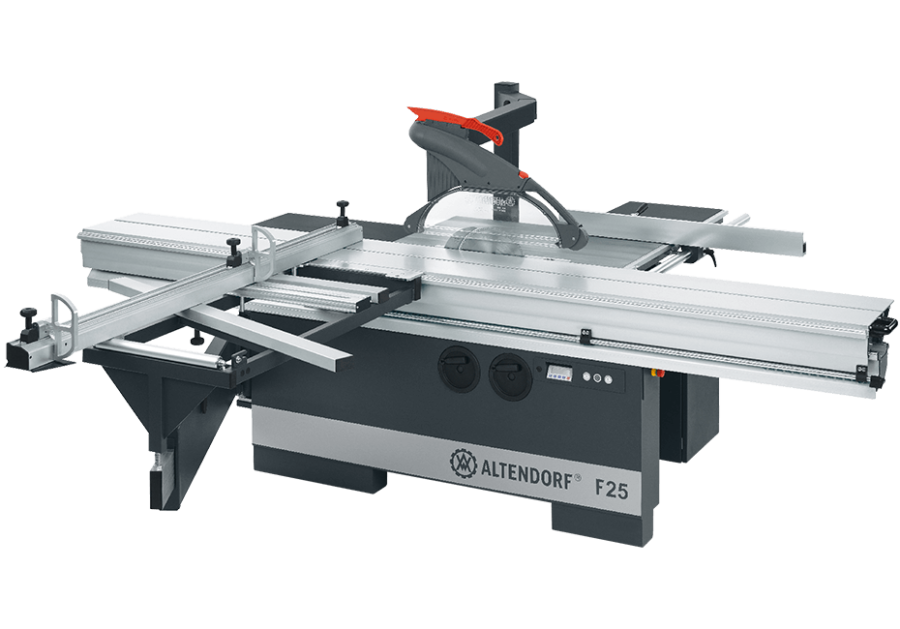

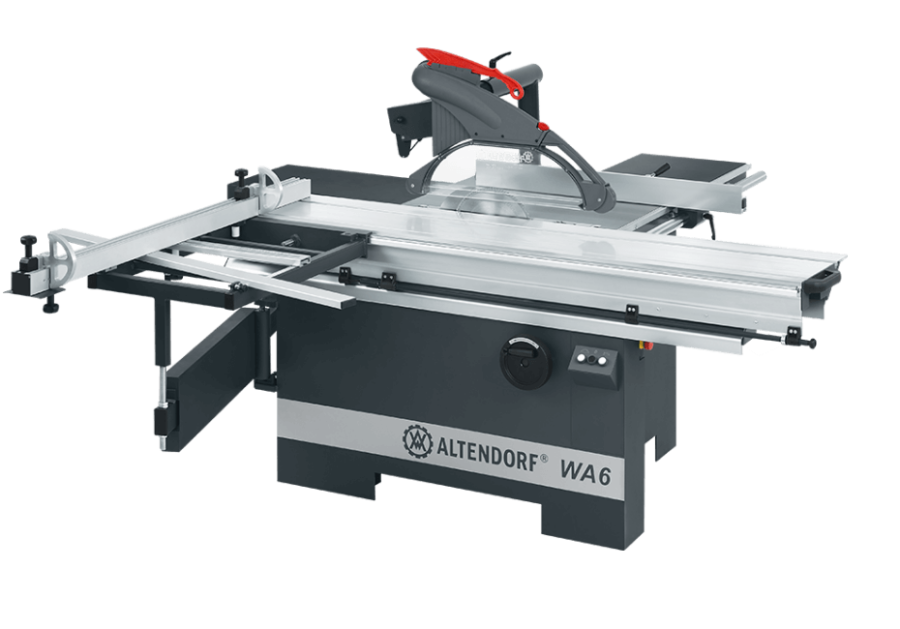

Altendorf machines for processing aluminium

With an Altendorf sliding table saw you are consistently relying on quality and reliability. And thus secure your company’s success in the long term.

The F 45 Configurator

Put together an F 45 that meets your exact needs. You will receive a direct offer.

Contact us

Would you like to find out more, do you have specific questions or need advice on our machines? We will advise you individually – simply contact our experts.