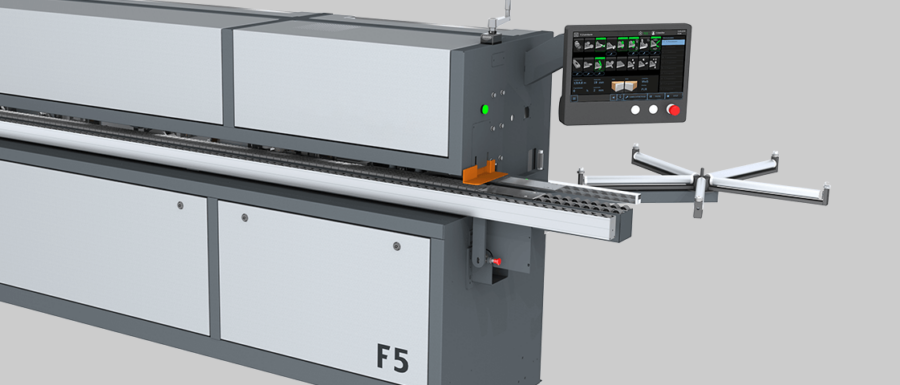

Edge machining at the highest level

Top quality, one step ahead

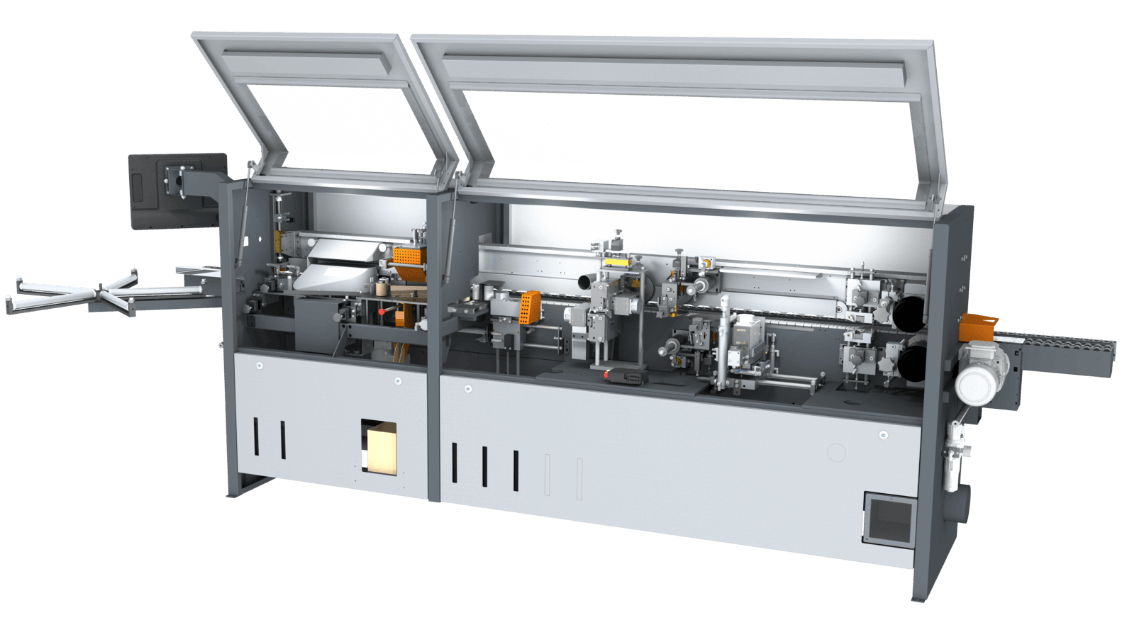

The HEBROCK F 5 produces edges to meet and exceed even the highest customer requirements. Premium craftsmanship requires perfection that our all-in-one model reliably delivers. Day after day. The F 5 is equipped with all the components you need for top-quality results, such as a jointing cutter, cross-cut saw, milling unit, radius scraper, corner rounding, flat scraper, and cleaning station. Want to achieve the ultimate finish? This high-performance model does plenty at the push of a button.

Main Features

Technical Features

- Feed speed 10 m/min

- Higher cover

- Greater ease of use

- Optional cleaning station

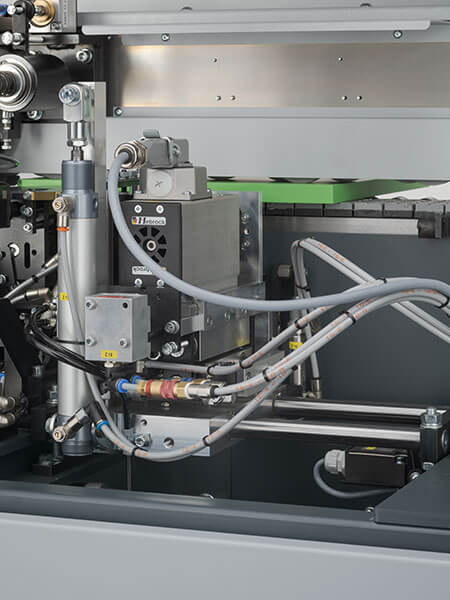

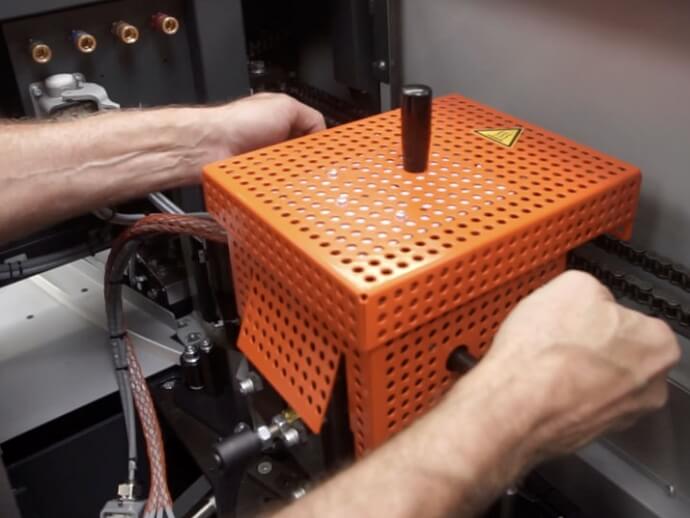

- Integrated adhesive changing device

- Compact frame design

Benefits

- Interchangeable glue pot can be heated in 3.5 mins

- Adhesive/colour change

- Flat scraper including dual keying

- Intuitive control

- Integrated cleaning station for polishing edge material

Software/Control

- 15“ LED touchscreen

- Easy-to-read display with integrated 3D feature

- Revolving and tilting control system

- USB interface

- Meter and running time counter

- Resistant to dust

Made for the highest demands

The main features of the F 5

More Features

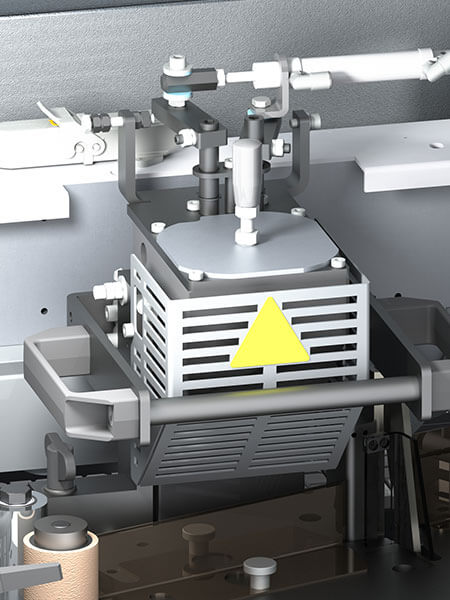

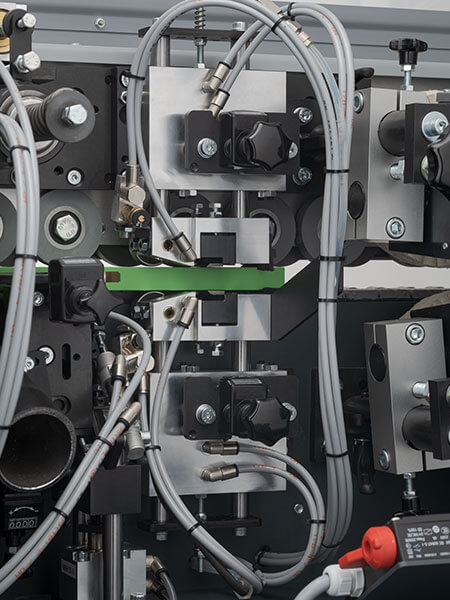

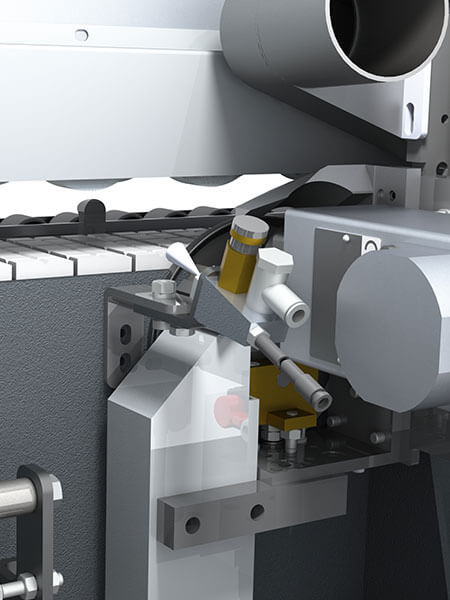

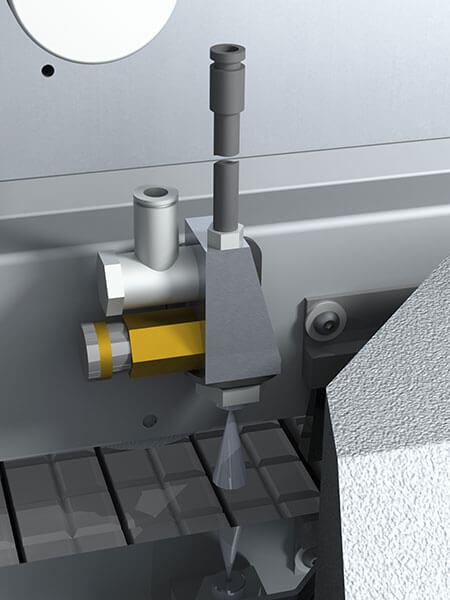

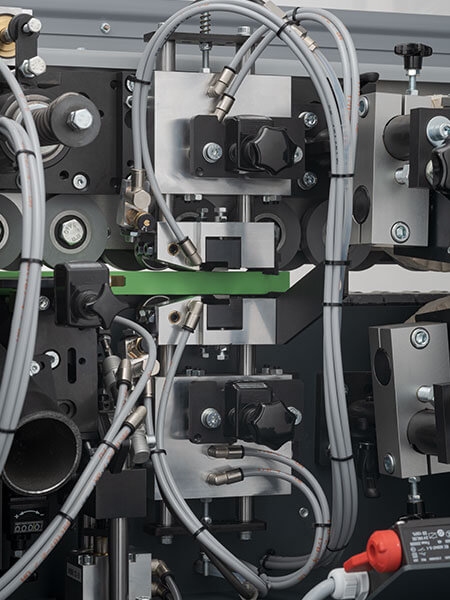

Release agent spraying unit

By applying the separating agent to the top and bottom of the workpiece, this prevents any excess adhesive residue from sticking to the workpiece Prior to edging, the spray system casts a fine layer of separating agent over the top and bottom of the workpiece edges. This prevents any excess adhesive from sticking to the workpiece. This option is recommended if regularly working with PUR adhesives.

Protection spraying unit

The lubricant is sprayed onto the edge surface via an additional fine nozzle to prevent damage to sensitive edges or the removal of film due to sensing rollers and sensing shoes.

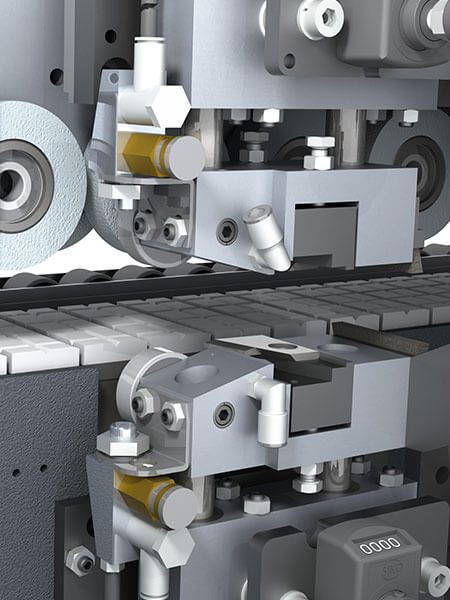

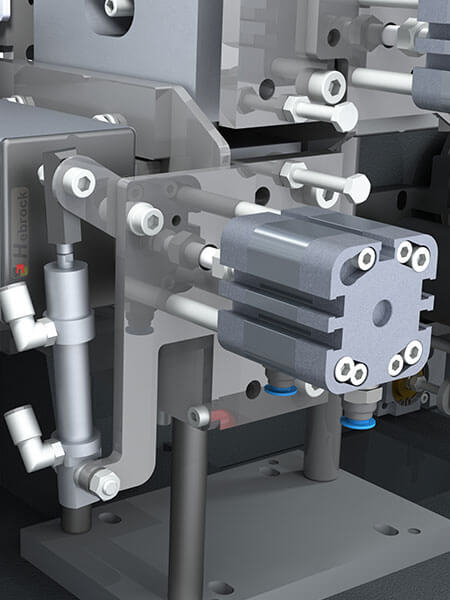

Pneumatic 3-point adjustment

By upgrading the milling to 3-point adjustment, the radius, chamfer and flush milling (combination blade) can be selected via the display. As a result, protective covers remain closed and this minimises set-up time.

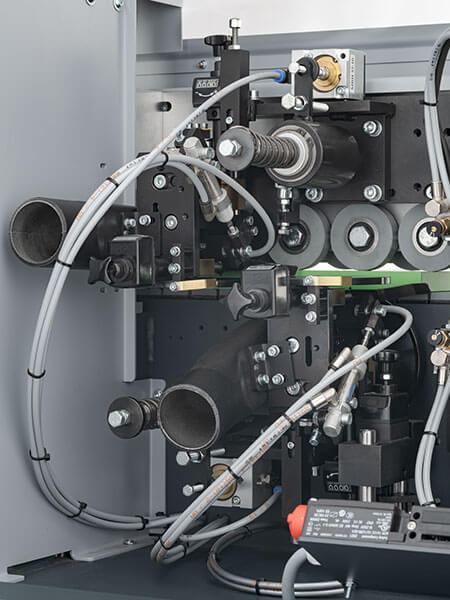

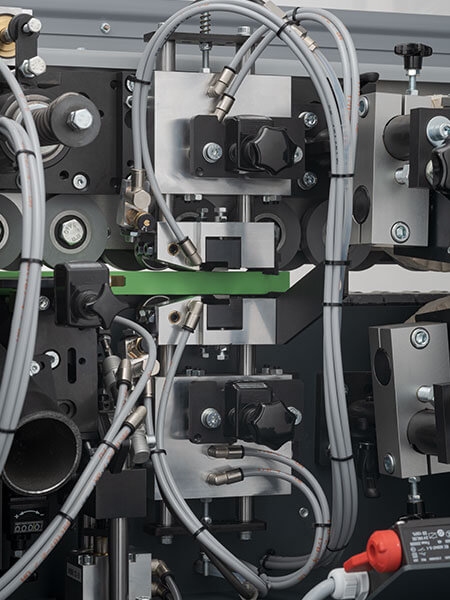

Radius profile scraper (including pneumatic disengagement)

Plane impacts or milling traces are smoothed down thanks to even cutting by the radius scraper. Settings are adjusted at the front of the machine. The upper and lower edge can be independently selected.

Equip your machine with the optional R2/R1 multi-radius scraper for a unique finishing result with classic ABS edges and modern thin edges. Simply choose the setting via the touchscreen display on the front of the machine – no tools required.

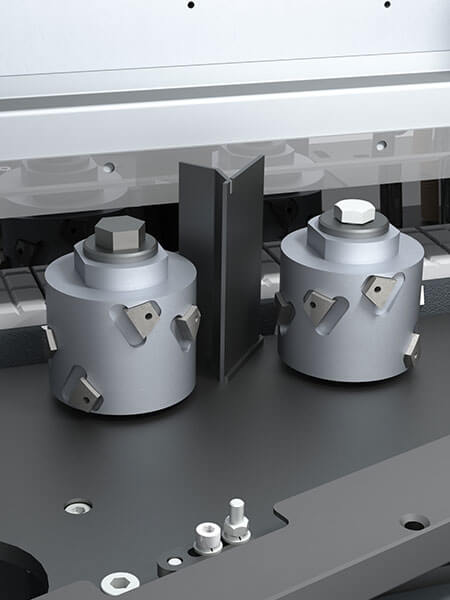

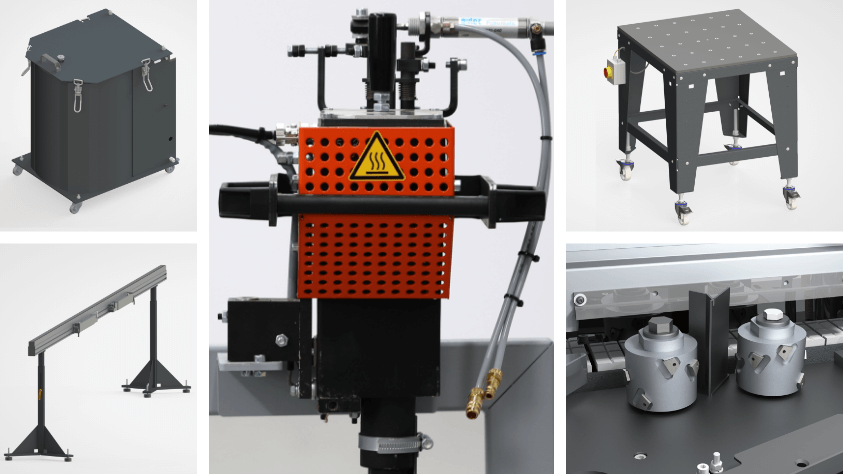

Corner rounding unit

Corner rounding optimally prepares you for any challenge when it comes to dealing with the front of the turning heads. Thanks to intelligent programming via the touchscreen display, individual sides and processing settings can be set.

Whether it’s the front and/or rear edge, radius or chamfer settings or choosing between an entire side or only the vertical edge, there are no limits here. The optional, interchangeable motor combined with our quick-change preliminary setup provides a rapid solution when dealing with different edge thicknesses.

Additional change motor for corner rounding

This AC motor optimally prepares your machine for ABS and thin edges.

Tools can be effortlessly changed and the finish improved. No manual reworking required (quick-change preliminary setup required).

More Features

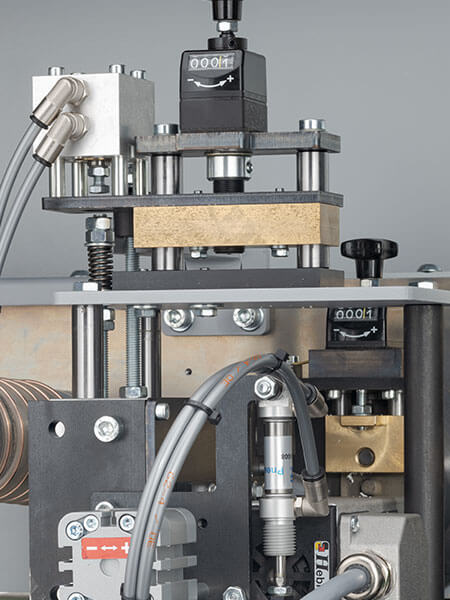

Surface scraper

Dynamically stored flat scraper ensures high production quality even for difficult materials. The wide contact surface precisely and gently scans the edge material to ensure consistent quality and removes adhesive residue and excess edges.

Indoor LED illumination

Interior machine lighting for clear setup and maintenance of your machine.

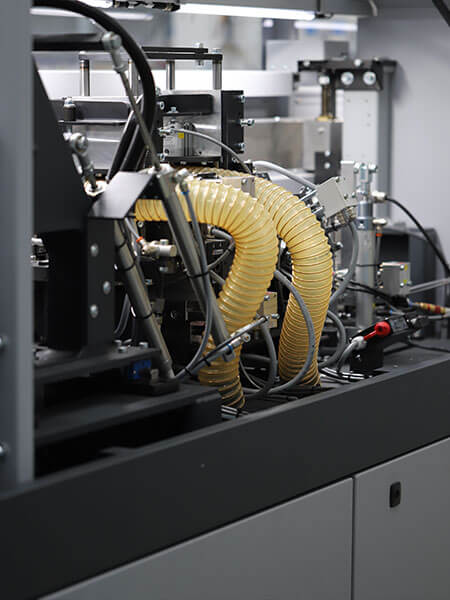

Cleaning station

The two polishing discs free the upper and lower panel from excess sprays, adhesive residue and lighten in the event of edge stress whitening. 2 x 0.18 kW motors, individually adjustable for consistent cleaning results when using various processing technologies.

Wheels

The warp-resistant machine base unit allows precise working for years to come.

Whether mass production of small parts or half-size panels, we guarantee a consistent finish each time you work. A well-thought-out extraction system, which requires just one central connection point to your extraction system, allows mostly mobile use of your HEBROCK edge banding machine even in small workshops. All inlet and outlets are found on the machine so that it can be moved as needed using our optional trolley for space-consuming work.

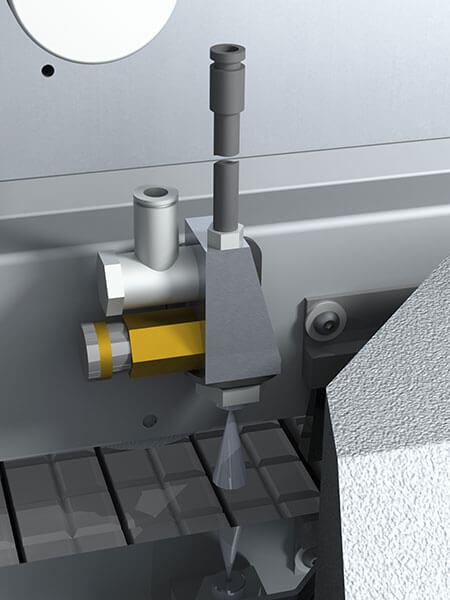

Nesting for milling station and radius scraper

Allows working with tool sharpening and pinhole drilling with a milling unit and radius scraper. The settings can be easily changed via the display on the front of the machine. Scanning of the workpieces takes place underneath the panel.

Specifications

Basic Features

|

|

Optional Features

|

|

Technical Details

| Max. pre-milling thickness | 2 mm |

| Max. edge thickness | 3 mm |

| Min/max workpiece thickness | 8 – 50 mm |

| Min. workpiece width | 80 mm |

| Min. workpiece length | 180 mm |

| Feed speed | approx. 10 m/min. |

| Ready for operation | approx. 3,5 min. |

| Max. power consumption | Ø approx. 7,4 kW |

| Electrical connection | 400 V – 3 Ph – 50 Hz |

| Machine dimensions (LxWxH) | approx. 4300 x 1450 x 1500 mm |

| Work table height | 850 mm |

| Extraction socket | Ø 1 x 140 mm |

| Weight | approx. 920 kg |

Accessories

Intelligent accessory for better support during your daily work. Almost always upgradable independent of the machine.

- Additional glue pot

- Pre-milling up to 50 mm workpiece thickness

- Air cushion table

- Additional roller bar

- PUR Box

The F 5 – as diverse as your projects

Plenty of scope for your requirements

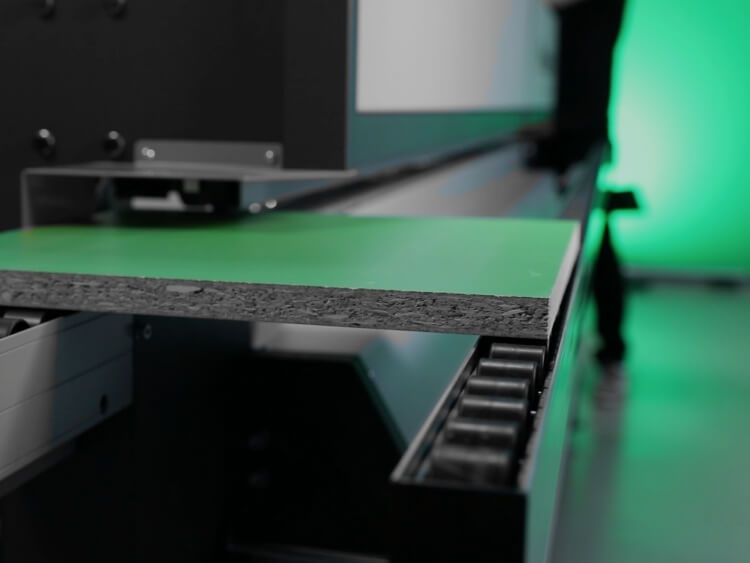

Wood

HEBROCK edge banding machines are the right choice for just about every type of wood. No matter whether it’s solid wood, chipboard, blockboards, MDF or multiplex, you can always expect precise, clean edge processing (including finishing).

Wood-like (HPL panels)

HEBROCK edge banding machines are the right choice for just about every type of wood. No matter whether it’s solid wood, chipboard, blockboards, MDF or multiplex, you can always expect precise, clean edge processing (including finishing).

Plastic

Edge banding of plastics, such as PP sandwich panels, is a key part of the craft.

With HEBROCK edge banding machines, you can enjoy productivity and flexibility as you work. At the same time, you’ll always offer top quality for your customers.

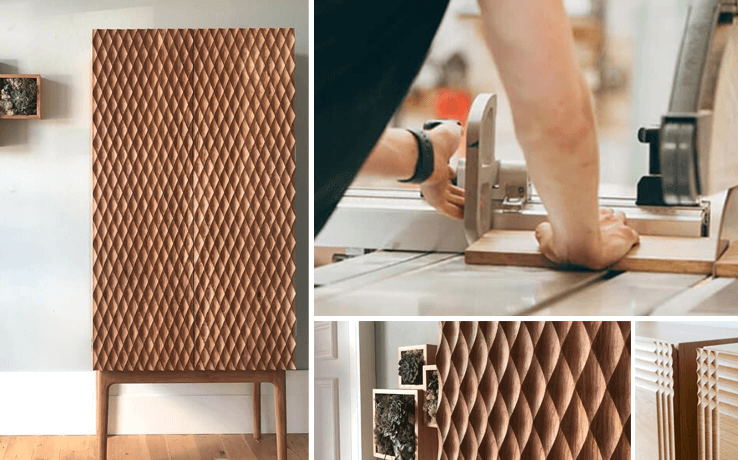

This is what the finest craftsmanship looks like

Top-quality craftsmanship can be seen in the details.

Clean edges are a key quality feature. These high-quality workpieces were produced with plenty of passion, great skill, and an edge banding machine from HEBROCK. Enjoy this small selection of works from our top performers in the F-SERIES!

Contact us

Would you like to find out more, do you have specific questions or need advice on our machines? We will advise you individually – simply contact our experts.

The service and spare parts service for Hebrock customers

Machine maintenance

Maximize the service life of your machine with a regular check-up. Wear parts are replaced, basic settings are checked. Trust the experienced Altendorf service technicians.

Spare parts service

Are you looking for the right spare part for your machine? It is guaranteed to be available in our large warehouses.

On site service

Our experienced service technicians will look at your defective sliding machine directly at your site and help you as promptly as possible.

Hebrock Downloads

Here you will find brochures, operating instructions and data sheets. All brochures and documents are available online – and just a few clicks away from download.