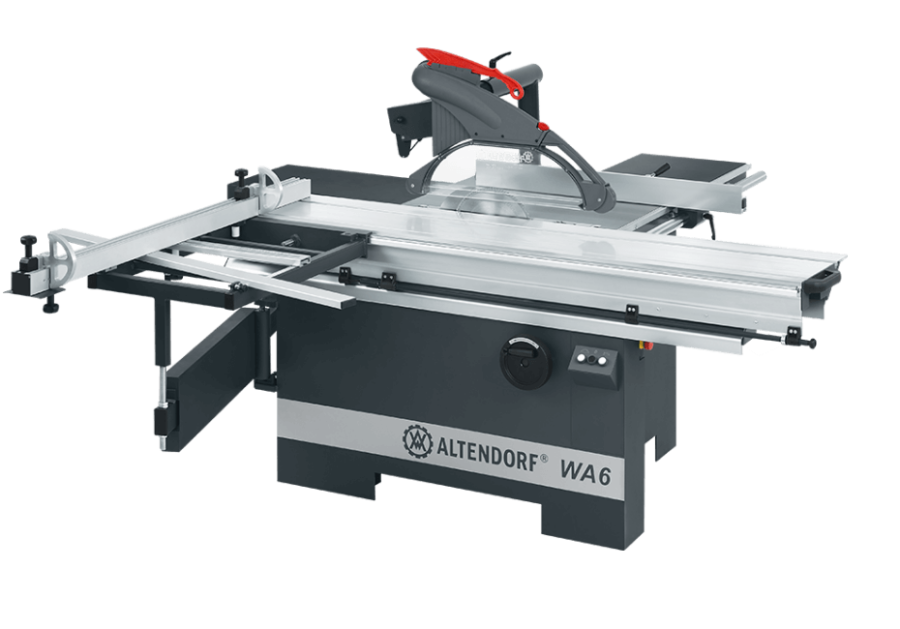

With an Altendorf sliding table saw, processing plastic is child’s play.

Plastics processors around the world appreciate the precision and versatility of the Altendorf sliding table saw – from simple cutting tasks to formatting tasks in aerospace technology.

Our sliding table saws for plastic are characterised by numerous equipment variants that have been specially developed for the complex challenges of plastic processing. This is Altendorf precision that inspires.

Discover the wide range of applications for plastics.

Engineering plastics are used in a variety of ways in different industries. Here we present some of the most common industries in which plastics play a significant role:

FAQs sliding table saws and plastics

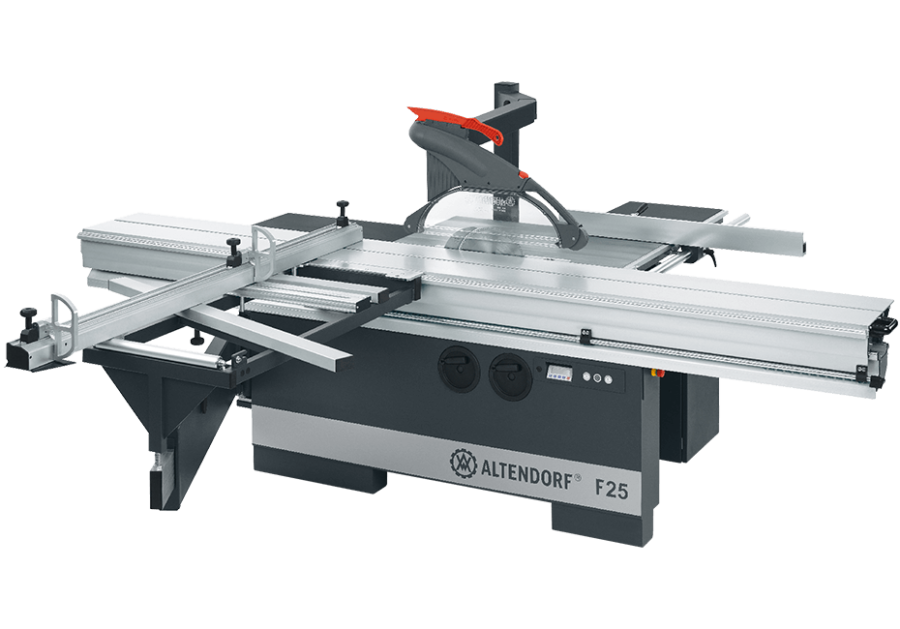

Which sliding table saw is the best?

Every Altendorf is equipped for small and large challenges.

If you want to process plastic, all our sliding table saws work to the highest quality – whether for simple cuts or complex mitres.

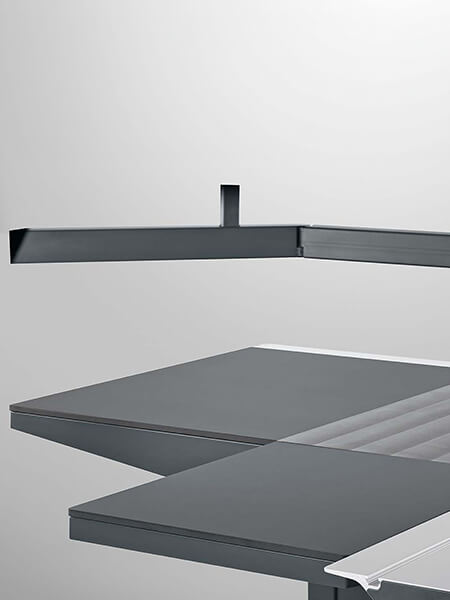

A wide range of options is available especially for plastics processors to cut strand or sheet material even more conveniently and precisely. Let our service support you in choosing the right sliding table saw for plastic.

Which plastics can Altendorf sliding table saws cut?

All commercially available plastics can be cut with an Altendorf sliding table saw.

z. e.g. PVC, PE, PP, POM or PMMA.

Our sliding table saws do not even shy away from complex composite materials such as carbon fiber composite panels – to the tenth of a millimeter! You should no longer do without an Altendorf for plastics processing.

Why process plastics with an Altendorf?

There are 5 reasons to process plastics with an Altendorf sliding table:

- Precision: +/- 1/10 mm accurate cutting

- Cutting quality: errors in the finished cut are virtually eliminated

- Material savings: materials are cut directly to finished size

- Versatility: from format cuts to surface angles and angles on the narrow surfaces of the workpieces

- Comfort: set stop flaps with digital displays to exact dimensions or position CNC-controlled axes simply at the touch of a button

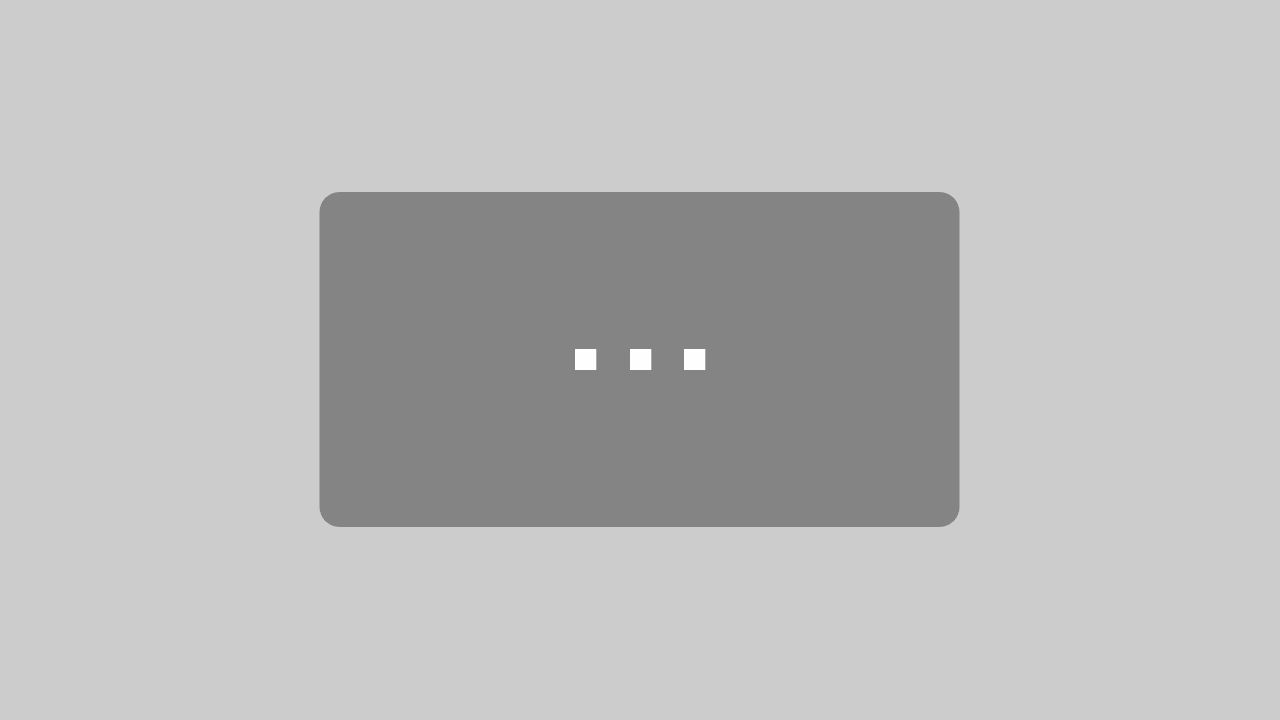

Equipment options for your new F 45 sliding table saw

Thanks to the modular machine concept, you can configure your F 45 individually – just as your application situation requires.

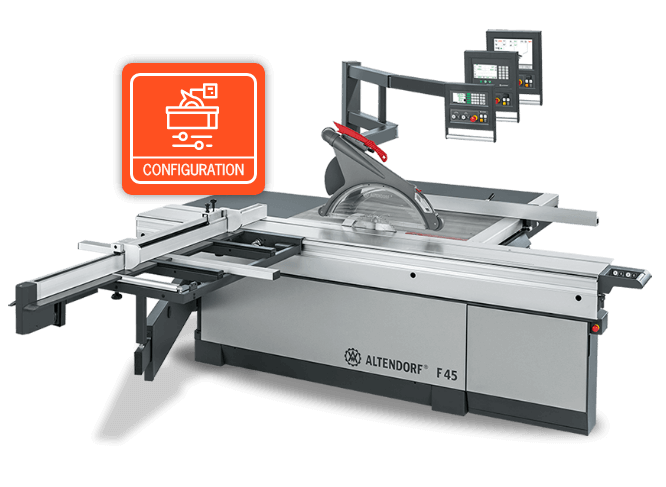

Altendorf machines for processing plastic

With an Altendorf sliding table saw you are consistently relying on quality and reliability. And thus secure your company’s success in the long term.

The F 45 Configurator

Put together an F 45 that meets your exact needs. You will receive a direct offer.

Contact us

Would you like to find out more, do you have specific questions or need advice on our machines? We will advise you individually – simply contact our experts.