Always in high-performance mode.

Quietly set your sights higher.

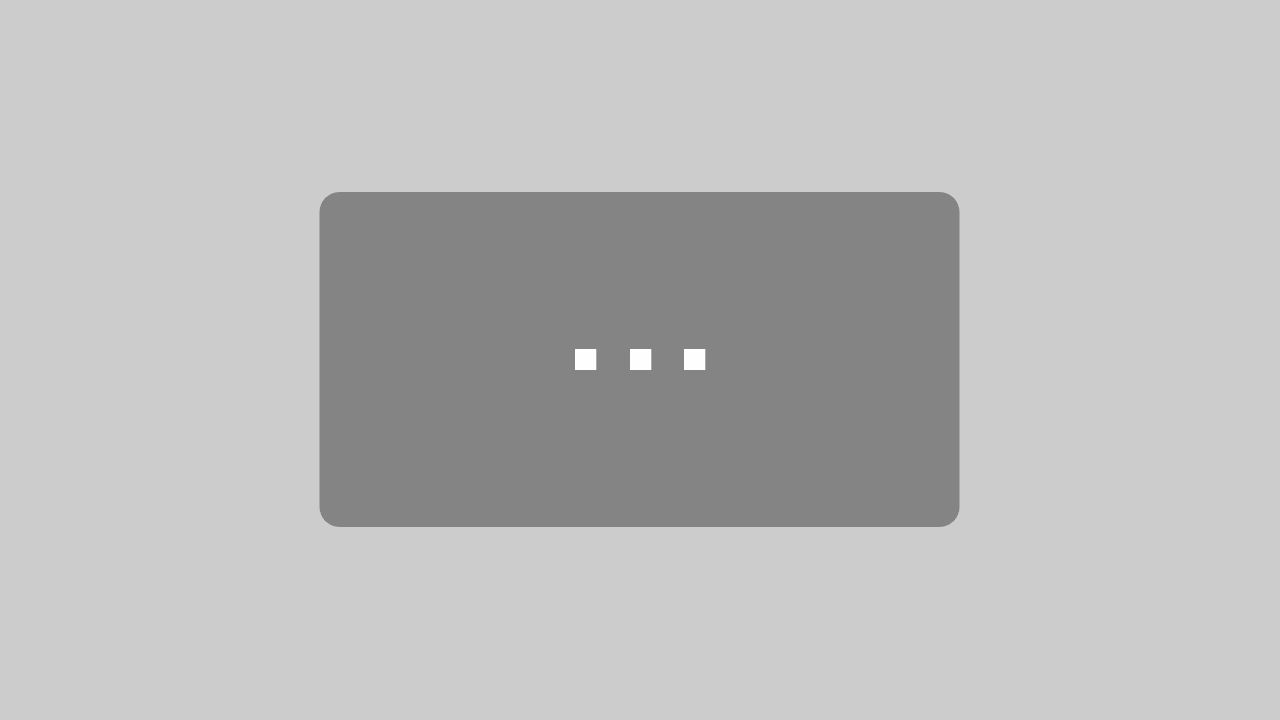

The HEBROCK K 36 achieves this with flying colours to deliver top performance each day. See for yourself. The robust, high-performance, and reliable machine is relentless when it comes to producing at a top level. Do you require extremely accurate edge processing? Perfect!

You have the option of equipping the machine with a second milling unit and multi-radius scraper for even more accurate results. Reach your goal with our all-time favourite.

Main Features

Technical Features

- Feed speed up to approx. 15 m/min*

- Greater ease of use

- Integrated glue changing device

- Compact frame design

*without corner rounding, depending on machine equipment

Benefits

- Interchangeable glue pot can be heated in 6 mins

- Adhesive/colour change

- Optional zero-joint technology

- Intuitive control

Software/Control

- 15” LED touchscreen

- Easy-to-read display with integrated 3D feature

- Revolving and tilting control options

- USB interface

- Meter and running time counter

- Resistant to dust

Made for the highest demands.

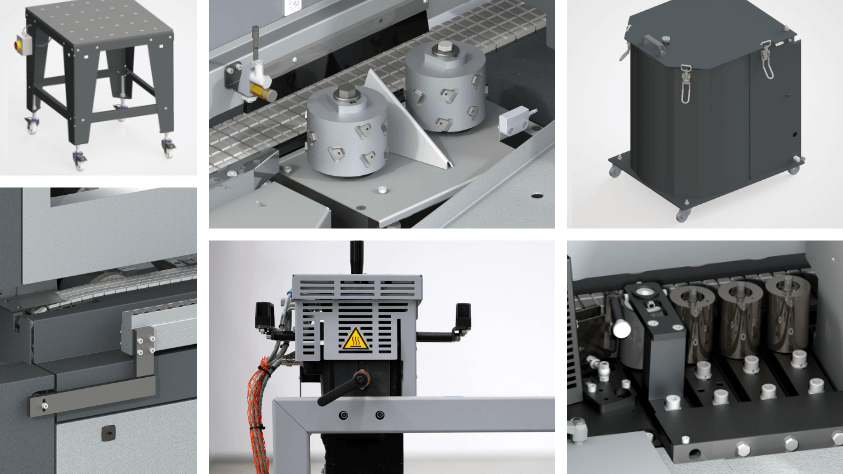

The main features of the K 36

More Features

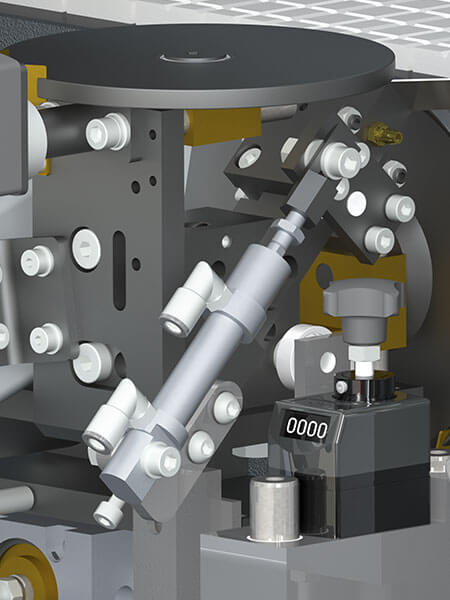

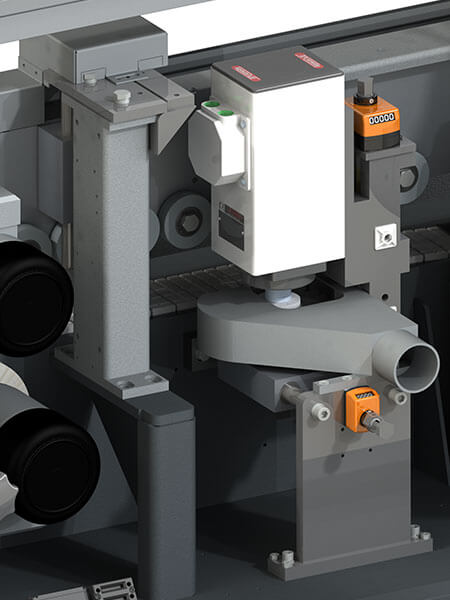

Axis package

Our axis package provides even more comfort. The panel and edge thickness, as well as the joint measurements, can be easily set using the display and the axes operate electro-mechanically. Easily store your settings in the respective programme and precisely repeat them.

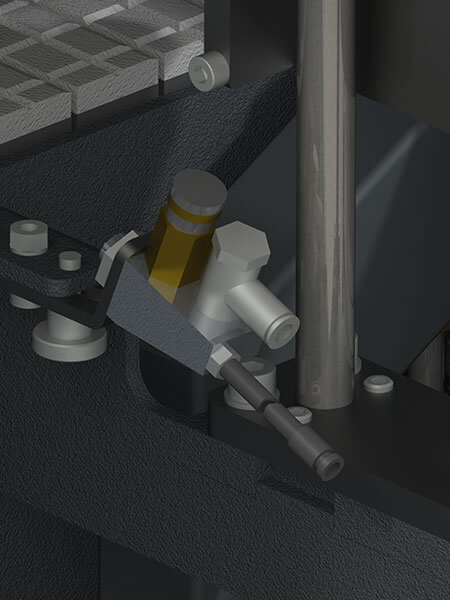

Glue level sensor

The optional glue level sensor for your interchangeable glue pots lets you keep track of things and avoid stoppages and gluing errors. The user is notified of low levels in good time via plain text notifications.

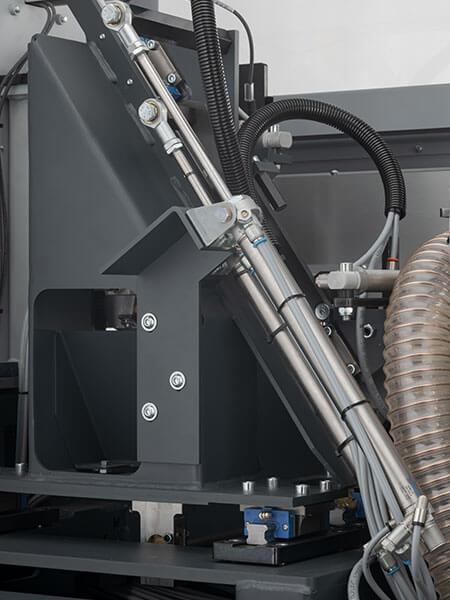

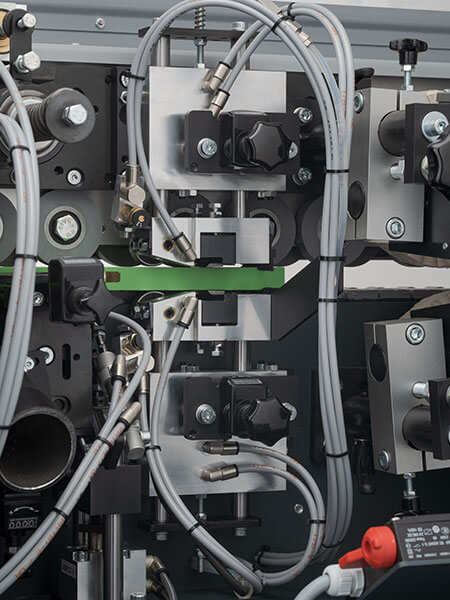

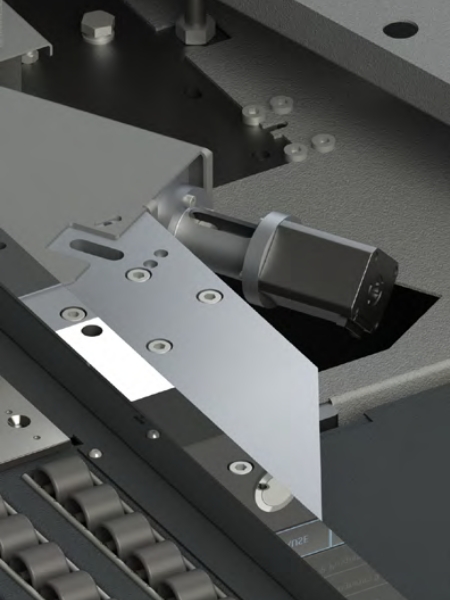

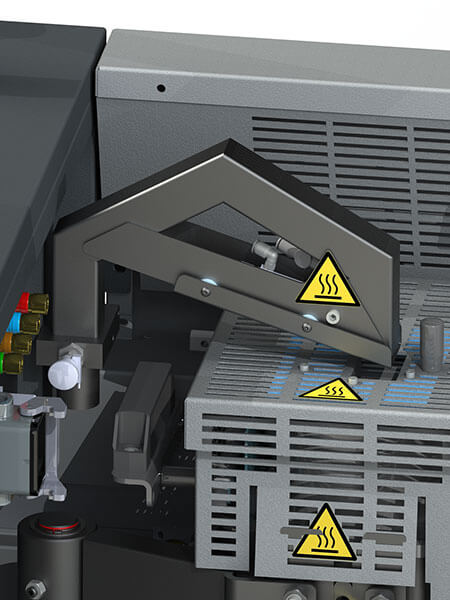

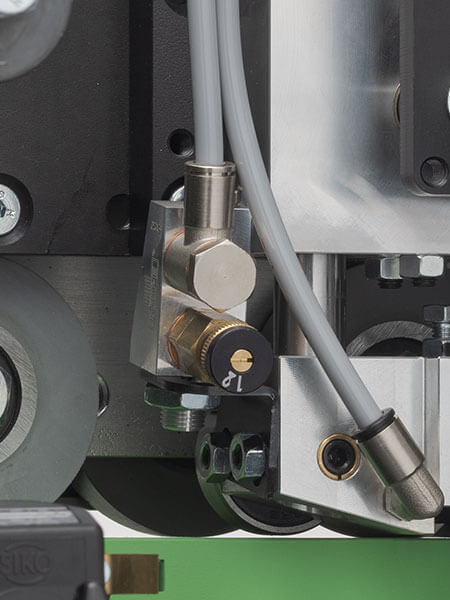

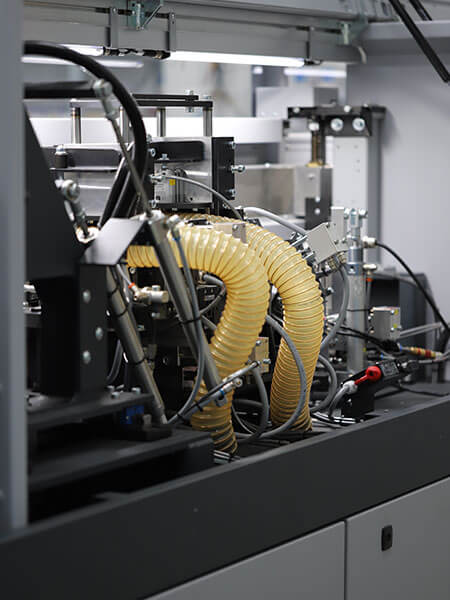

Release agent spraying unit

Prior to edging, the spray system casts a fine layer of separating agent over the top and bottom of the workpiece edges.

This prevents any excess adhesive from sticking to the workpiece. This option is recommended if regularly working with PUR adhesives.

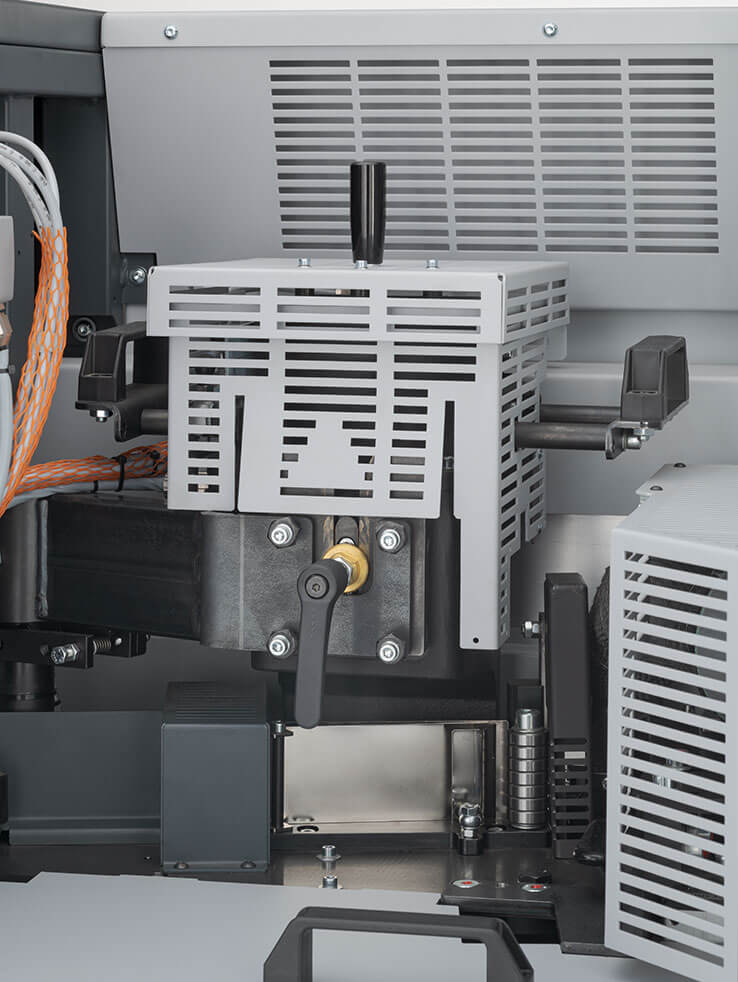

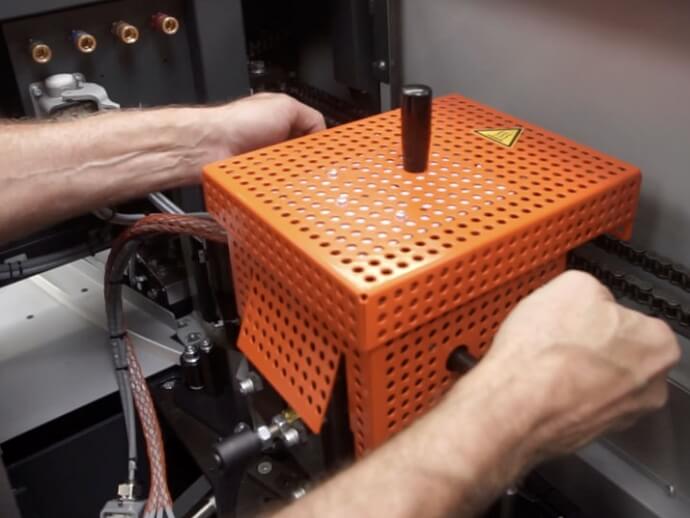

Quick change heating pot

- Ready for operation in just 6 minutes

- Standard interchangeable glue pots with stop function for rapid

- change of colour or technology (EVA/PUR)

- Tool-free change of glue pot

- Simplified cleaning of glue pot in a matter of minutes

- Teflon coating for effortless cleaning

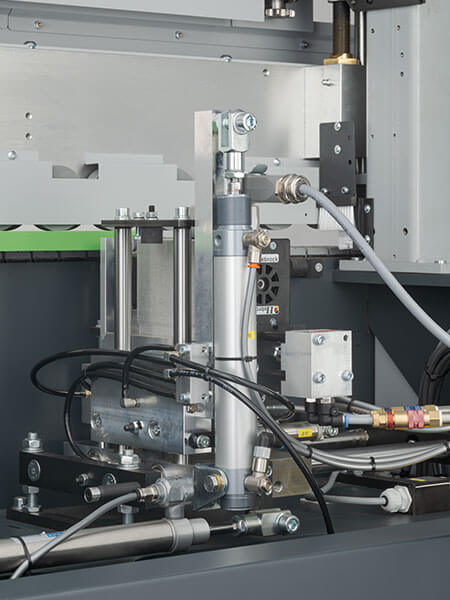

Automatic glue pot refilling system

A large storage tank for up to 5 kg of granules ensures maximum efficiency.

The glue pots are filled automatically so that even high cycle times can be easily handled without the need for manual filling.

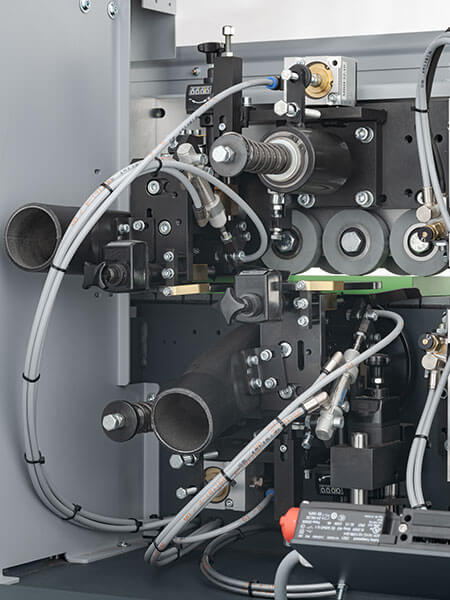

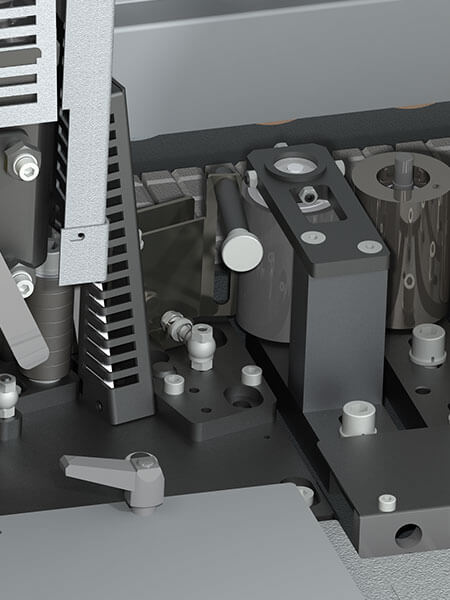

Pressure zone

Four solid pressure rollers are spring-loaded and close off the top and bottom edges of the panels to guarantee perfect results for various materials and surfaces. For the 8 mm package, the first roll is powered mechanically to drive the solid wood edge bands.

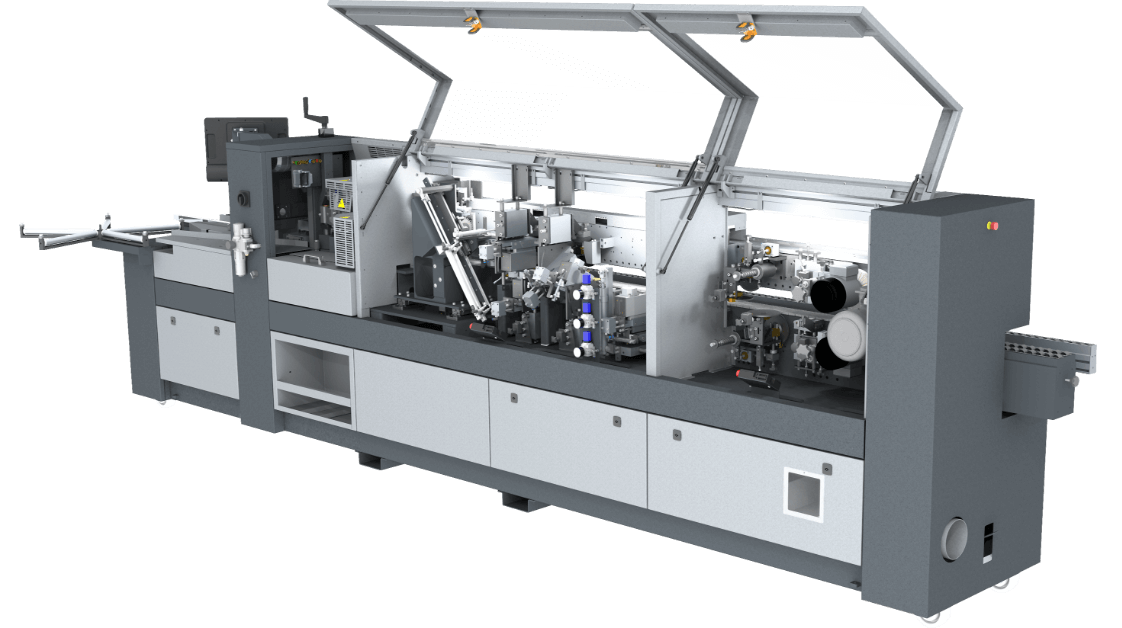

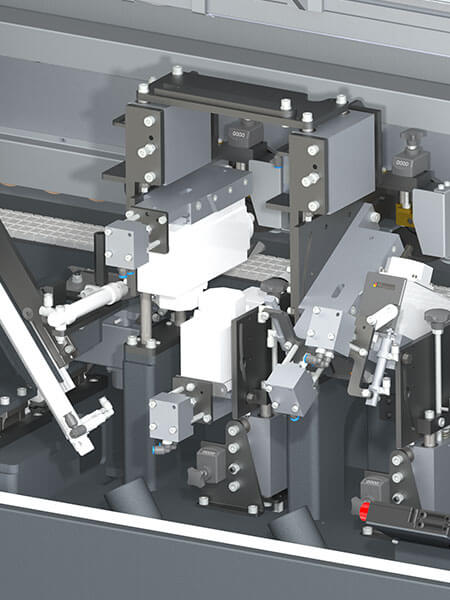

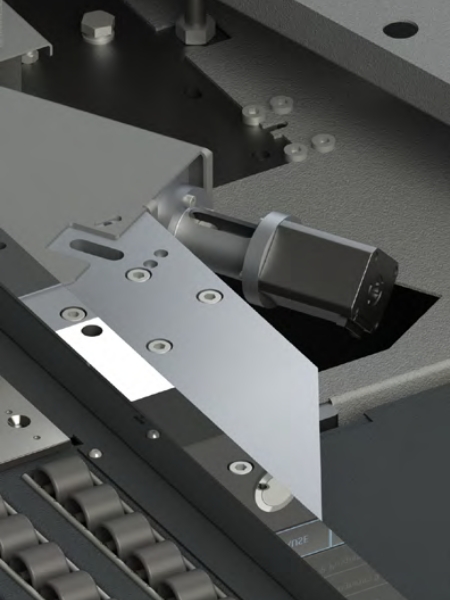

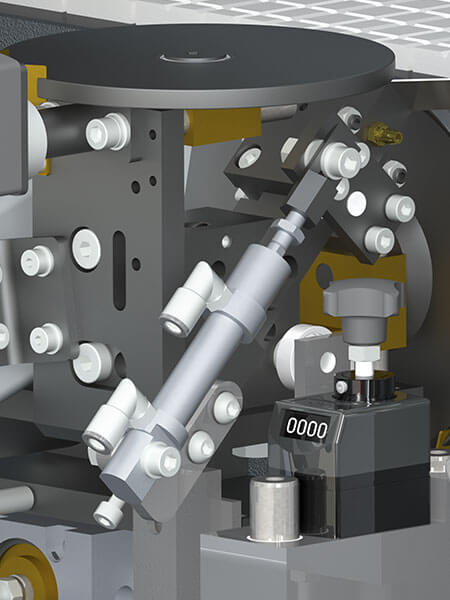

Milling station

This combined milling unit allows you to choose between radius / 10° chamfer or flush trimming (combined unit). The standard setting for radius / 10° chamfer is conveniently situated at the front of the machine.

The optional 3-point adjustment allows even more flexible processing for different requirements. Adjustments are instant and reduce downtime to a minimum.

Expand your applications and process different edge thicknesses with greater flexibility thanks to step milling for R2/R1/ chamfer and the second milling station.

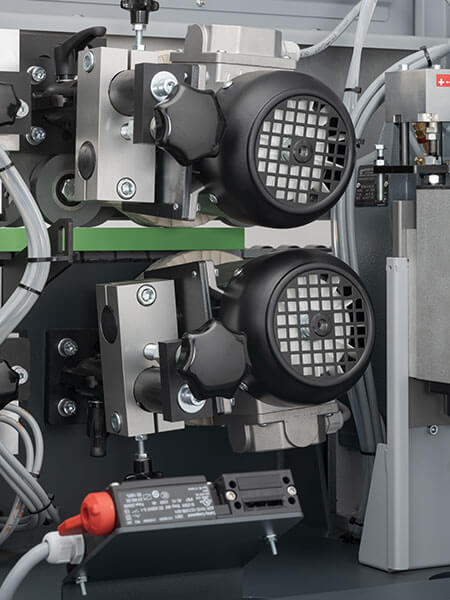

2nd milling station

Thanks to the second milling station, you can produce various radiuses with greater flexibility. Greater chip weights can be realised thanks to pre-milling and precision milling. A 30° chamfer can also be produced by manually adjusting the unit.

Multi-radius scraper

The multi-radius scraper allows you to process R2 and R1 radii without having to change the machine settings for flexible processing of different radii. The radius settings can be individually selected or saved as a programme.

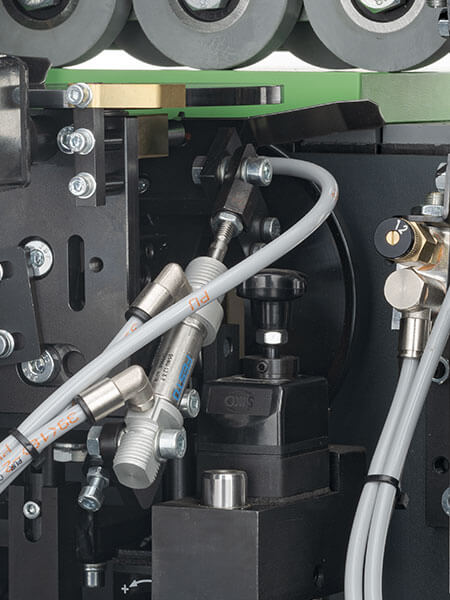

Cleaning agent spraying unit

This spray system applies the cleaning agent to the top and bottom of the workpiece. Applying the cleaning agent followed by the cleaning station removes any sprays, adhesives and impurities.

Changeable motor for corner rounding

The preset interchangeable motor including tool allocation reduces machine set-up time when changing the front head radius. The quick-change preliminary setup allows the motor to be changed quickly without the need for any additional settings.

Nesting for milling station and radius profile scraper

Allows working with tool sharpening and hinge hole drilling with a milling unit and radius scraper. The settings can be easily changed via the display on the front of the machine. Scanning of the workpieces takes place underneath the panel.

Groove saw

The grooving saw unit reduces the need for subsequent labour-intensive tasks on the milling machine. Use the grooving saw either for processing tongue and groove joints or on the panel for rear-panel grooves (non-combinable). Processing can take place across the entire length of the workpiece or as needed.

Wheels

The warp-resistant machine base unit enables precise working all year round. Whether mass production of small parts or half-size panels, we guarantee a consistent finish each time you work.

A well-thought-out extraction system, which requires just one central connection point to your extraction system, allows mostly mobile use of your HEBROCK edge banding machine even in small workshops. All inlet and outlets are found on the machine so that it can be moved as needed using our optional trolley for space-consuming work.

Indoor LED illumination

Interior machine lighting for clear setup and maintenance of your machine.

Specifications

Basic Features

|

|

Optional Features

|

|

Technical Details

| Max. pre-milling thickness | 3 mm |

| Max. Edge thickness | 3 mm |

| Min/Max. workpiece thickness | 8 – 60 mm |

| Min. workpiece length | 120 mm (at 7 m/min feed rate) |

| Min. workpiece width | 80 mm |

| Feed speed | up to approx. 15 m/min.* (*without corner rounding, depending on machine equipment) |

| Ready for operation | approx. 6 min. |

| Max. power consumption | Ø approx. 14 kW |

| Electric connection | 400 V – 3 Ph – 50 Hz |

| Machine dimensions (LxWxH) | approx. 5250 x 1230 x 1430 mm |

| Work table height | 940 mm |

| Extraction socket | 1 x 80 mm, 1 x 140 mm |

| Weight | approx. 1750 kg |

Accessories

Intelligent accessories, independent of the machine mostly retrofittable at any time

- 8 mm version

- Pre-milling up to 60 mm workpiece thickness

- Heatable infeed fence

- Pre set-up return system (barbaric)

- Glue pot suction hood

- Additional change over quick heating pot

- PUR Box

- Air cushion table

- Additional roller bar

The K 36 – as versatile as your projects.

Plenty of scope for your requirements.

Wood

HEBROCK edge banding machines are the right choice for just about every type of wood. No matter whether it’s solid wood, chipboard, blockboards, MDF or multiplex, you can always expect precise, clean edge processing (including finishing).

Wood-like (HPL panels)

These HPL panels are available in various dimensions, thicknesses and surface designs. Thanks to HEBROCK edge banding machines, they are easy and flexible to work with.

Our machines are suitable for various material dimensions.

Observe the respective technical profile.

Plastics

Edge banding of plastics, such as PP sandwich panels, is a key part of the craft.

With HEBROCK edge banding machines, you can enjoy productivity and flexibility as you work. At the same time, you’ll always offer top quality for your customers.

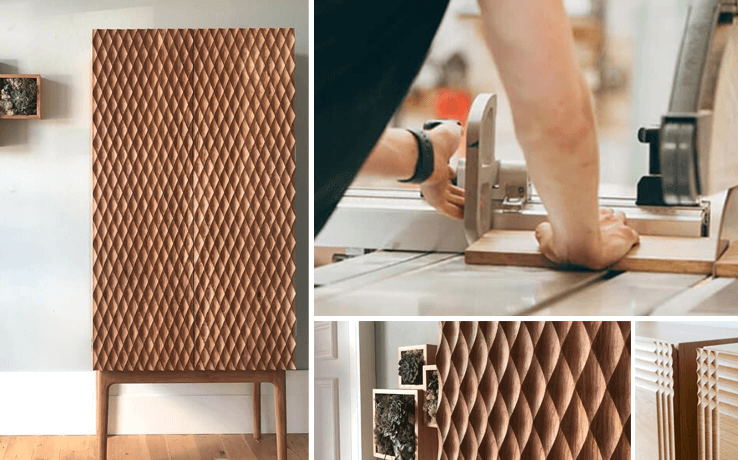

This is what fine craftsmanship looks like

Top-quality craftsmanship can be seen in the details.

Clean edges are a key quality feature. These high-quality workpieces were produced with plenty of passion, great skill, and an edge banding machine from the HEBROCK K-SERIES. Enjoy this small selection of works from our high performers!

Your Contact Partner

We are here to assist you and look forward to your call.

The service and spare parts service for Hebrock customers

Machine maintenance

Maximize the service life of your machine with a regular check-up. Wear parts are replaced, basic settings are checked. Trust the experienced Altendorf service technicians.

Spare parts service

Are you looking for the right spare part for your machine? It is guaranteed to be available in our large warehouses.

On site service

Our experienced service technicians will look at your defective sliding machine directly at your site and help you as promptly as possible.

Hebrock Downloads

Here you will find brochures, operating instructions and data sheets. All brochures and documents are available online – and just a few clicks away from download.